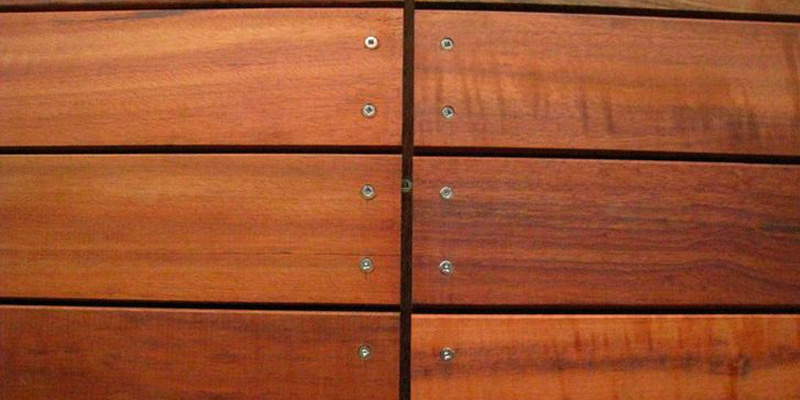

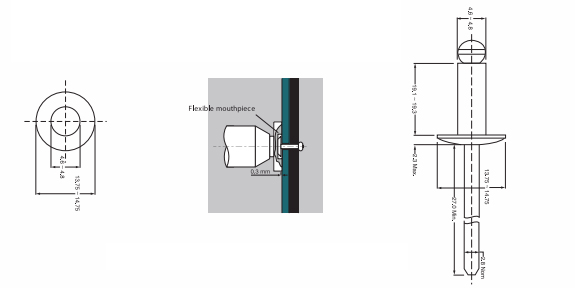

Sustainable and long-term construction requires cost effective solutions. Pacific product & solutionsCladdings are just that! Long service life, lengthy maintenance intervals and the recyclable components are essential to Facades that stands the economy of time.